Donghaixiang group company is incorporate textile dyeing, plastic, package, melt-blown nowoven.medical equipment etc. of large group company. As one of the professional China KN95 Mask Suppliers and an OEM KN95 Mask company, we offer wholesale KN95 Mask Suppliers for sale online. Our company attaches great importance to the quality of the product, technology accumulation, and technologi cal innovation. Currently we have obtained more than 80 invention patents.

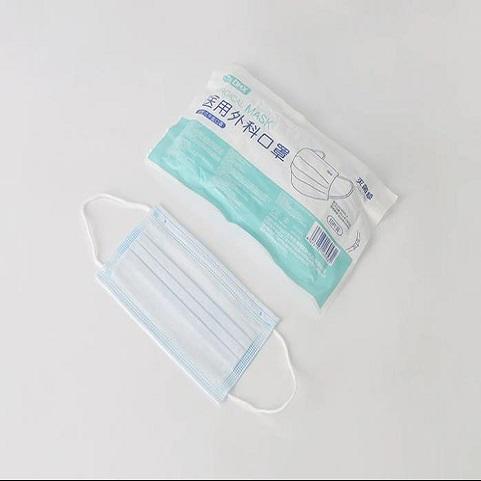

Zhejiang Donghaixiang Medical Device Co., Ltd. is a wholly-owned subsidiary of donghaixiang group specializing in the production of medical devices and protective articles. Our KN95 Mask through ISO13485 medical device quality management system. It has all kinds of relevant qualifications, obtained thecer tification of EUCE and FDA, and has 40 intelligent mask production lines. It has 24 N95 production equipment lines, It can develop, produce and sell medical surgical masks and disposable medical ports Masks, disposable masks, N95 protective masks and other products, and equipped with a full set of mask detection equipment, can independently test varioustypes of masks.

The company takes the responsibility of people , selects the quality materials, adopts the advanced equipment, establishes a perfect quality management system, provides high-quality KN95 Mask products and protects the health of users.

Enterprise establishment

Patent Certificate

Company employees

Production Lines

We has all kinds of relevant qualifications, obtained thecer tification of EUCE and FDA.

Design High Quality Disposable Virus Sampling Tube Factory In the wake of global health crises, the importance of sustainable practices in disposable virus sampling tube manufacturing has gained significant attention. These tubes play a crucial role in disease detection and control, and ensuring their production aligns with sustainable principles is imperative. This article explores the sustainability practices employed by disposable virus sampling tube factory and their impact on the environment, society, and the healthcare industry. disposable virus sampling tube factory are increasingly prioritizing sustainability throughout their manufacturing processes. One key aspect is the responsible sourcing of materials. These factories opt for eco-friendly materials, such as recycled plastics or biodegradable alternatives, to small environmental impact. By reducing reliance on virgin materials, they lower carbon emissions and conserve natural resources. Furthermore, energy efficiency measures are implemented to reduce the environmental footprint of disposable virus sampling tube factory. This includes investing in energy-efficient machinery, optimizing production processes, and utilizing renewable energy sources whenever possible. By reducing energy consumption and greenhouse gas emissions, these factories contribute to mitigating climate change and promoting environmental stewardship. Waste reduction and recycling initiatives are also integral to sustainability practices in disposable virus sampling tube manufacturing. Factories implement waste management strategies to small waste generation and maximize recycling rates. Scrap materials are often recycled or repurposed, reducing landfill waste and conserving resources. Additionally, some factories partner with recycling facilities to ensure responsible disposal of waste materials. Moreover, water conservation efforts play a significant role in sustainable manufacturing practices. disposable virus sampling tube factory implement water-saving technologies, such as closed-loop water systems and water-efficient equipment, to small water usage and wastewater discharge. By reducing water consumption and pollution, these factories help protect freshwater resources and ecosystems. In addition to environmental considerations, disposable virus sampling tube factory prioritize social responsibility in their operations. This includes ensuring safe and fair working conditions for employees, respecting human rights, and supporting local communities. Ethical sourcing practices are adopted to ensure that raw materials are obtained from suppliers who uphold labor rights and ethical standards. Collaboration and transparency are key principles guiding sustainability practices in disposable virus sampling tube manufacturing. Factories engage with stakeholders, including customers, suppliers, and regulatory agencies, to foster dialogue and transparency regarding sustainability initiatives. By collaborating with partners across the supply chain, these factories work towards shared sustainability goals and drive positive change within the industry. Furthermore, certification and compliance with international standards demonstrate a commitment to sustainability and quality in disposable virus sampling tube manufacturing. Factories may obtain certifications such as ISO 14001 for environmental management systems or adhere to guidelines set forth by organizations like the Global Reporting Initiative (GRI) or the Sustainable Development Goals (SDGs). Compliance with these standards ensures accountability and credibility in sustainability efforts. Looking ahead, the future of disposable virus sampling tube manufacturing lies in continuous innovation and improvement of sustainability practices. Factories are investing in research and development to explore alternative materials, eco-friendly production techniques, and innovative solutions for waste reduction and energy efficiency. By embracing innovation and embracing sustainability, these factories are poised to make a positive impact on public health and the environment. In conclusion, sustainability practices in disposable virus sampling tube manufacturing are essential for addressing environmental, social, and economic challenges while meeting the growing demand for healthcare products. By prioritizing responsible sourcing, energy efficiency, waste reduction, water conservation, social responsibility, collaboration, and transparency, these factories are advancing sustainability in the healthcare industry and contributing to a healthier and more sustainable future.

ODM Custom Disposable Virus Sampling Tube Factory Maker In the global battle against infectious diseases, the reliability and accuracy of virus sampling are critical. Disposable virus sampling tube factory play a crucial role in ensuring the quality and integrity of these essential tools. This article explores the rigorous standards and quality assurance measures employed in the production processes of disposable virus sampling tube factory. disposable virus sampling tube factory are tasked with producing sterile and reliable sampling tubes used for collecting and transporting specimens for virus testing. The importance of these tubes cannot be overstated, as they directly impact the accuracy of diagnostic tests and the effectiveness of disease surveillance efforts. As such, maintaining stringent quality assurance standards throughout the production process is imperative. One of the primary aspects of quality assurance in disposable virus sampling tube factory is the selection and testing of raw materials. The quality of materials used in the production of sampling tubes directly influences their performance and reliability. Factory standards dictate thorough testing and evaluation of raw materials to ensure they meet specifications for purity, sterility, and compatibility with the intended use. Furthermore, disposable virus sampling tube factory adhere to strict manufacturing processes to small the risk of contamination and ensure product consistency. Cleanroom environments are commonly employed to prevent airborne particles and microbial contaminants from compromising the integrity of the tubes. Additionally, automated manufacturing equipment and controlled processes help maintain precision and consistency in tube production. Quality control measures are integrated at various stages of the manufacturing process to identify and mitigate potential defects or deviations from specifications. Visual inspections, dimensional measurements, and functional tests are performed to verify the quality and performance of sampling tubes before they are packaged and sterilized. Any tubes found to be non-compliant are promptly identified and removed from the production line. Sterilization is a critical step in the production of disposable virus sampling tubes to ensure they are free from microbial contamination. disposable virus sampling tube factory employs validated sterilization methods, such as gamma irradiation or ethylene oxide gas treatment, to achieve sterility while preserving the integrity of the tubes. Strict monitoring and validation protocols are implemented to verify the effectiveness of sterilization processes. In addition to meeting regulatory requirements, disposable virus sampling tube factory often implement additional quality management systems to further enhance product quality and customer satisfaction. Certification to international standards such as ISO 13485 for medical devices demonstrates a commitment to quality management and compliance with industry-ideal practices. Continuous improvement initiatives and feedback mechanisms allow factories to identify areas for enhancement and optimize their processes over time. Environmental sustainability is another consideration for disposable virus sampling tube factory aiming to smaller their environmental footprint. Efforts may include optimizing energy usage, reducing waste generation, and sourcing eco-friendly materials where possible. By integrating sustainability practices into their operations, factories can contribute to environmental conservation while maintaining high standards of product quality and safety. Moreover, collaboration and communication with stakeholders are essential aspects of quality assurance in disposable virus sampling tube factory. Engaging with healthcare professionals, regulatory authorities, and end-users facilitates the exchange of knowledge and insights, enabling factories to better understand customer needs and expectations. This collaborative approach ensures that factory standards remain aligned with evolving industry requirements and ideal practices. In conclusion, quality assurance is paramount in the production of disposable virus sampling tubes to ensure the accuracy and reliability of diagnostic testing and disease surveillance efforts. disposable virus sampling tube factory adheres to rigorous standards throughout the production process, from raw material selection to sterilization and quality control. By upholding these standards, factories contribute to the global efforts to combat infectious diseases and safeguard public health.

China OEM Disposable Virus Sampling Tube Factory Company In the face of global health crises, such as the COVID-19 pandemic, the demand for reliable virus sampling tools has surged. Disposable virus sampling tube factory play a critical role in meeting this demand by ensuring the production and distribution of essential sampling supplies to healthcare facilities, testing centers, and research institutions worldwide. This article explores the operations of disposable virus sampling tube factory and their efforts to meet the growing global demand. disposable virus sampling tube factory operates at the intersection of healthcare, manufacturing, and logistics, with a primary focus on producing high-quality sampling tubes for the collection and transportation of viral specimens. These tubes are essential for diagnostic testing, epidemiological surveillance, and research purposes, providing healthcare professionals and scientists with vital tools for detecting and monitoring infectious diseases. The operations of disposable virus sampling tube factory are characterized by precision, efficiency, and adherence to strict quality standards. From the selection of raw materials to the manufacturing process and final packaging, every step is meticulously controlled to ensure the integrity and reliability of the sampling tubes produced. Quality control measures are implemented at each stage of production to detect and prevent any defects or contamination, thus upholding the high standards of safety and efficacy. To meet the global demand for disposable virus sampling tubes, factories often operate on a large scale, with production lines running around the clock to maximize output. Advanced manufacturing technologies, such as automated assembly systems and robotic packaging equipment, enable factories to achieve high levels of productivity while maintaining consistency and accuracy in the production process. Additionally, efficient supply chain management practices ensure the timely procurement of raw materials and the swift distribution of finished products to customers worldwide. In response to the COVID-19 pandemic, many disposable virus sampling tube factory have ramped up their production capacity and expanded their operations to meet the exceptional surge in demand. Governments, healthcare organizations, and international agencies have collaborated closely with manufacturers to facilitate the rapid scale-up of production and ensure the availability of sampling supplies in regions heavily impacted by the pandemic. This collaborative effort has been instrumental in strengthening global preparedness and response efforts against the spread of the virus. Furthermore, disposable virus sampling tube factory have played a crucial role in supporting research and development efforts aimed at improving diagnostic testing methods and developing new technologies for virus detection. By supplying researchers and innovators with the necessary tools and resources, these factories contribute to the advancement of scientific knowledge and the development of innovative solutions for combating infectious diseases. Collaborations between manufacturers, academia, and government agencies have facilitated the exchange of expertise and facilitated the translation of research findings into practical applications. As the global demand for disposable virus sampling tubes continues to evolve, factories must remain agile and adaptable to address emerging challenges and opportunities. This includes investing in research and development initiatives to enhance product performance and usability, as well as exploring new technologies and materials to improve manufacturing efficiency and sustainability. Additionally, collaboration and information sharing among manufacturers, regulatory authorities, and public health agencies are essential for ensuring the continued safety and efficacy of sampling tubes and promoting global health security. In conclusion, disposable virus sampling tube factory play a vital role in meeting the global demand for essential sampling supplies and supporting public health efforts to combat infectious diseases. Through their operations, these factories ensure the production of high-quality sampling tubes while upholding stringent quality standards and facilitating innovation in diagnostic testing and research. By working collaboratively with stakeholders across the healthcare ecosystem, disposable virus sampling tube factory contribute to the collective effort to safeguard public health and address global health challenges.

Supply Sale Wholesale Disposable Virus Sampling Tube Factory Innovation in healthcare is constantly evolving to meet the challenges posed by emerging infectious diseases. One crucial aspect of healthcare innovation is the development of disposable virus sampling tube factory. These facilities play a vital role in producing the essential tools needed for efficient and accurate virus detection, contributing significantly to disease surveillance, diagnosis, and control efforts worldwide. This article explores the innovative solutions offered by disposable virus sampling tube factory and their impact on healthcare. disposable virus sampling tube factory are at the forefront of healthcare innovation, providing solutions that are essential for the detection and monitoring of infectious diseases. These facilities specialize in the mass production of disposable tubes specifically designed for collecting and transporting viral samples from patients to testing laboratories. By utilizing advanced manufacturing processes and quality control measures, these factories ensure the production of high-quality, reliable sampling tubes that meet stringent healthcare standards. The importance of disposable virus sampling tube factory became especially evident during global health crises such as the COVID-19 pandemic. The rapid spread of the virus highlighted the critical need for efficient and scalable virus testing infrastructure. disposable virus sampling tube factory played a pivotal role in meeting this demand by ramping up production to supply healthcare systems with the necessary tools for widespread testing campaigns. One of the key innovations offered by disposable virus sampling tube factory is the development of user-friendly and versatile sampling tube designs. These tubes are engineered to facilitate easy and safe collection of various types of viral samples, including nasal swabs, throat swabs, saliva samples, and more. Additionally, some factories offer customization options, allowing healthcare providers to choose tube configurations that ideal suit their specific testing protocols and equipment requirements. Moreover, disposable virus sampling tube factory prioritize efficiency and scalability in their manufacturing processes. By leveraging automation, robotics, and advanced production techniques, these facilities can produce large quantities of sampling tubes quickly and cost-effectively. This scalability is essential for responding to fluctuating demand and ensuring timely access to testing supplies during public health emergencies. Innovation in healthcare also extends to the materials used in disposable virus sampling tube manufacturing. Many factories are exploring eco-friendly and sustainable alternatives to traditional plastics, such as biodegradable polymers and recyclable materials. By adopting environmentally responsible practices, these factories smaller their carbon footprint and contribute to global efforts to reduce plastic waste in healthcare settings. Furthermore, disposable virus sampling tube factory is continuously improving their products through ongoing research and development initiatives. This includes exploring novel materials, refining tube designs, and integrating advanced features such as barcoding for sample tracking and identification. These innovations enhance the accuracy, reliability, and efficiency of virus testing processes, ultimately piloting to better patient outcomes and public health outcomes. The impact of disposable virus sampling tube factory extends beyond individual healthcare settings to encompass broader public health initiatives. By providing healthcare systems with the tools they need to conduct widespread virus testing and surveillance, these factories play a crucial role in early detection, containment, and mitigation of infectious disease outbreaks. This proactive approach is essential for preventing the spread of viruses and safeguarding global health security. In conclusion, innovation in healthcare, as exemplified by disposable virus sampling tube factory, is essential for addressing the challenges posed by infectious diseases. These facilities offer innovative solutions that are instrumental in virus detection, surveillance, and control efforts. By prioritizing quality, efficiency, sustainability, and ongoing innovation, disposable virus sampling tube factory contribute to advancing healthcare and protecting public health on a global scale.